Secure the Load: A Complete Guide to Pallet Banding

If you’re in the business of shipping or storing goods, you know how important it is to keep your pallet loads secure. Pallet banding is an essential practice that provides stability, prevents damage and maintains the safety of both the goods being transported and the people handling them. In this guide, we’ll walk you through the ins and outs of pallet banding, introduce you to the innovative VELCRO® Brand LOGISTRAP® pallet straps and share some essential safety tips to keep your operations running smoothly.

Why Pallet Banding Matters

Pallet banding plays a huge role in logistics, warehousing and transportation. When goods are stacked onto pallets, they need to be secured in place to prevent them from shifting or toppling during movement. This is particularly important for businesses that transport fragile items, heavy-duty equipment or products that are vulnerable to external forces.

If a load isn’t properly secured, it may shift in transit, which can lead to product damage, financial losses and potential safety hazards. Plus, unstable pallets can be difficult to handle with forklifts or other warehouse lifting equipment, slowing down operations and increasing the risk of workplace accidents.

Beyond just preventing physical damage, proper pallet banding contributes to the overall efficiency of a supply chain. Securely strapped pallets allow for smoother loading and unloading processes, which reduces the time needed to handle shipments. This, in turn, leads to cost savings and increased productivity for businesses. Finally, with growing concerns about environmental impact, using sustainable and reusable pallet banding solutions, such as Velcro pallet straps, helps reduce waste and promotes eco-friendly logistics practices.

How Can VELCRO® Brand LOGISTRAP® Pallet Straps Help?

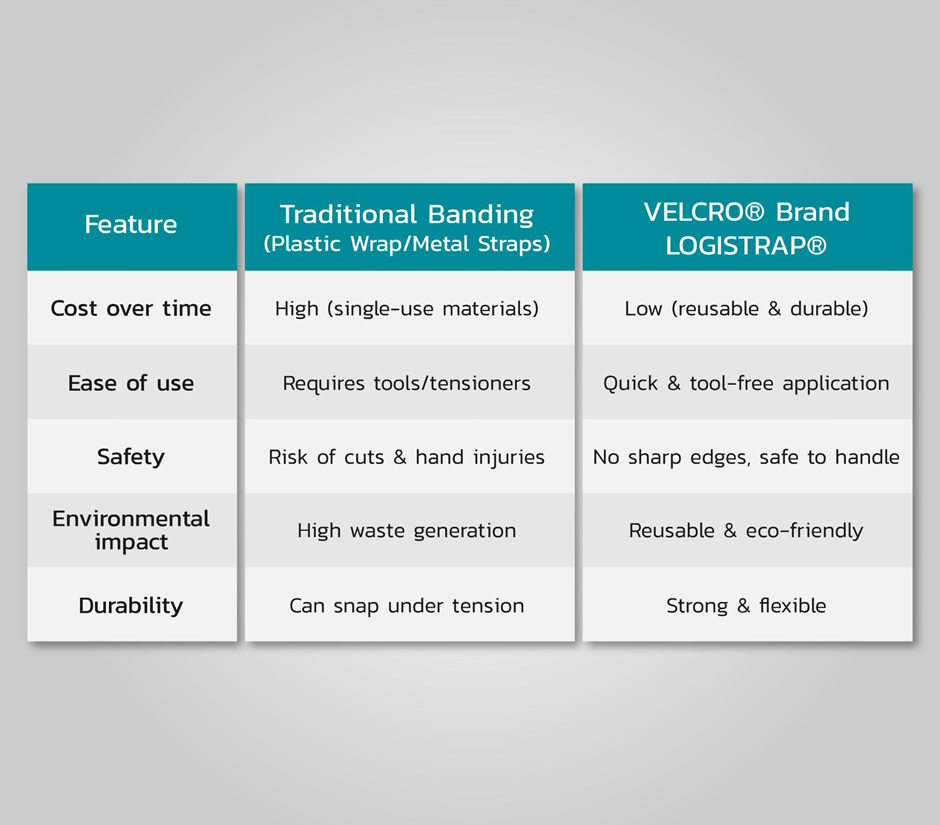

Traditional pallet banding methods often involve plastic wrap, metal bands or single-use straps, which can be cumbersome to apply and remove. They also generate a significant amount of waste, leading to increased disposal costs and environmental concerns. However, the introduction of VELCRO® Brand LOGISTRAP® has revolutionised pallet banding by offering a reusable, durable and efficient alternative that outperforms traditional methods.

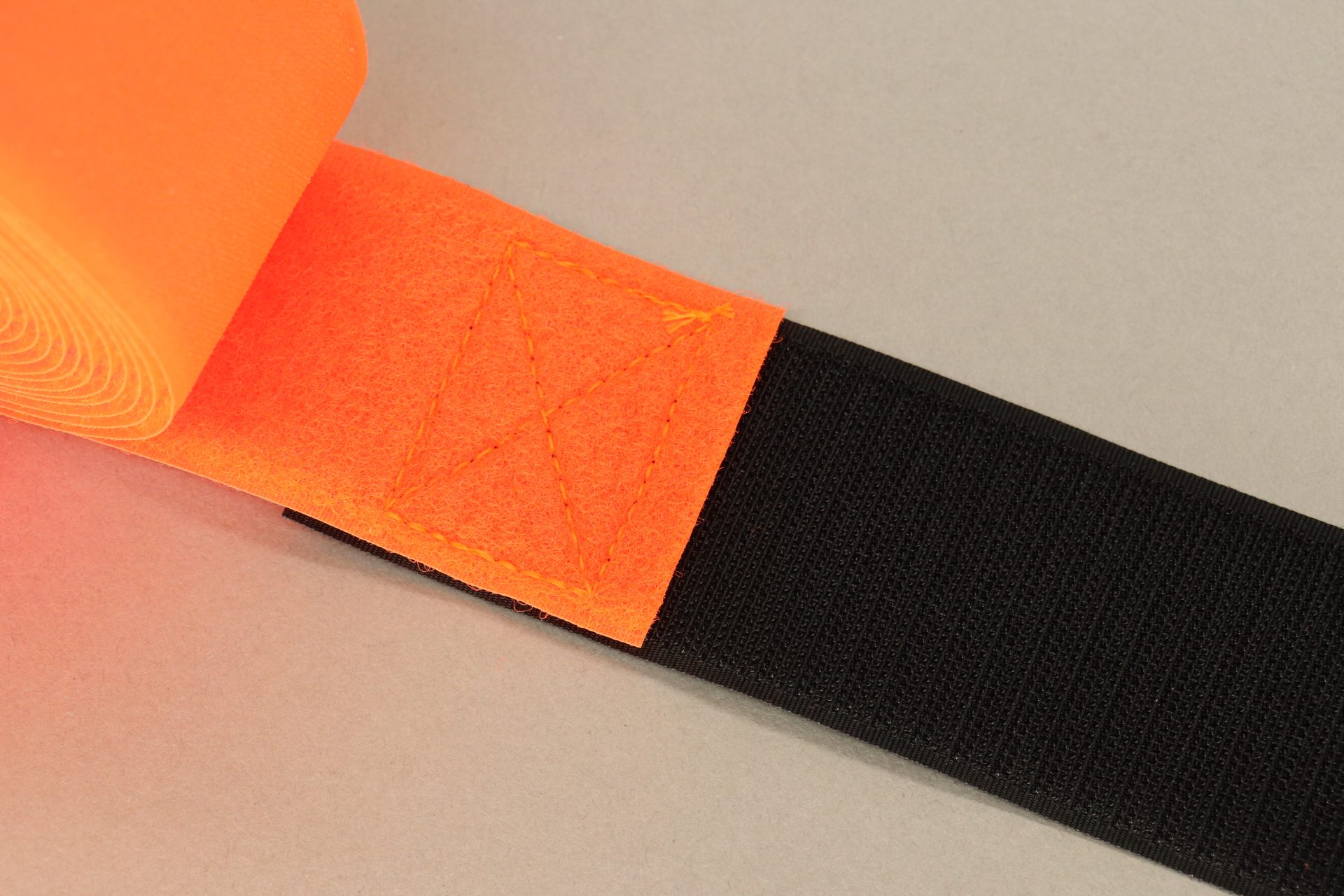

Unlike single-use plastic wraps, LOGISTRAP® is designed to be used multiple times, making it a cost-effective and environmentally friendly option. These straps are constructed with a strong yet flexible hook-and-loop fastening system that allows for quick and easy application. There’s no need for special tools or complicated mechanisms; simply wrap the strap around the pallet load and secure it with the hook-and-loop closure. This simplicity not only saves time but also improves workplace safety by reducing the risk of injuries associated with metal banding tools.

Another big benefit of LOGISTRAP® is that it is gentle on goods. Traditional metal bands or plastic wraps can exert excessive pressure on fragile products, leading to potential damage. In contrast, Velcro pallet straps provide a secure hold without compromising the integrity of the packaged items. Additionally, these straps are available in different lengths and strengths, allowing businesses to choose the right specifications for their specific load requirements. Whether you need to secure lightweight boxes or heavy-duty industrial materials, LOGISTRAP® provides a versatile and reliable solution.

Step-by-Step Guide to Securing Pallets with LOGISTRAP®

If you are new to using Velcro pallet straps or looking for best practices on how to optimise your pallet banding process, follow these simple steps to ensure your loads are properly secured.

Step 1: Assess Your Load

Before selecting the appropriate LOGISTRAP®, evaluate the size, weight and stability of your pallet load. Consider the type of goods being transported and how they are stacked on the pallet. If the load consists of lightweight or fragile items, you may require multiple straps to distribute pressure evenly and prevent movement.

Step 2: Position the Strap

Once you have determined the right LOGISTRAP® for your load, position the strap around the pallet, ensuring it encircles the stacked items evenly. Avoid placing the strap too high or too low on the load, as this can lead to instability. Ideally, the strap should be positioned at points where it can provide the most support while keeping the goods in place.

Step 3: Secure the Strap

Tighten the strap around the pallet load and press the hook-and-loop closure together to create a firm hold. One of the biggest benefits of LOGISTRAP® is its adjustability. If the strap feels too loose or too tight, simply reposition it for a more secure fit. Unlike traditional banding methods that may require cutting or reapplying materials, LOGISTRAP® allows for quick and easy adjustments.

Step 4: Inspect the Pallet

After securing the strap, perform a quick stability test by giving the pallet a gentle push. If you notice any movement, adjust the strap accordingly. Making sure that the load remains firmly in place is crucial to prevent shifting during transit or storage.

Safety First: Guidelines and PPE for Pallet Banding

While LOGISTRAP® makes pallet banding safer and more straightforward, it is essential to follow safety guidelines and use the correct personal protective equipment (PPE) to minimise risks during application and removal.

Always make sure that you use the appropriate tools for the job. LOGISTRAP® does not require any special cutting tools or tensioners, which significantly reduces the risk of hand injuries. However, workers should still wear protective gloves to prevent abrasions, especially when handling rough materials or lifting heavy loads. Safety glasses are also recommended to shield the eyes from any unexpected snaps or flying debris.

On top of this, maintaining a clutter-free workspace is crucial for preventing accidents. Keep the area around pallet banding stations clear of obstructions to allow for smooth and safe handling. Proper training on the correct use of LOGISTRAP® is also essential to ensure all workers understand how to apply, adjust and remove the straps efficiently.

Why Choose MPD Hook & Loop for Your Pallet Banding Needs?

At MPD Hook & Loop, we are committed to providing high-quality Velcro pallet straps that simplify logistics operations while enhancing safety and sustainability. We offer a wide range of VELCRO® Brand products, including the innovative LOGISTRAP® pallet straps, providing businesses access to durable and cost-effective solutions for securing their loads.

Our expert team is always on hand to provide guidance and help you select the best pallet tie-down straps for your specific needs. We take pride in offering competitive pricing without compromising on quality, making us the preferred choice for companies looking to optimise their pallet banding processes.

Velcro Pallet Straps at Competitive Prices

Securing pallet loads effectively is a critical component of logistics and warehouse management, but with VELCRO® Brand LOGISTRAP®, businesses can achieve a safer, more efficient and environmentally friendly approach to pallet banding. By following the correct application methods, adhering to safety guidelines, and choosing high-quality Velcro pallet straps from MPD Hook & Loop, you can significantly enhance your operations and reduce costs associated with damaged goods and excessive waste.

Browse our full range of products online, or for more information about us, please get in touch with our helpful team.