The Crucial Role Pallet Straps Play in Material Handling

To transport stock safely to a new location, pallet loading must be done carefully and correctly, without the risk of damage. Without the right tools, however, this can be challenging, which is where pallet straps come in. Businesses across various industries utilise pallet straps to help secure materials onto a pallet before handling them. In this handy guide, you can discover everything you need to know about these straps.

Why Pallet Straps Matter in Material Handling

Pallet straps play a crucial role in securing, stabilising, and protecting goods during transportation and storage. Whether in a warehouse, on a lorry, or during international shipping, proper strapping helps prevent damage, improves safety, and enhances operational efficiency. Pallet straps are used to secure materials as they are moved and transported, stopping them from falling or becoming damaged.

The Key Benefits of Using Pallet Straps

If you need to secure your materials before handling them, pallet straps are often the best option. Read on to discover the key benefits of using pallet straps, from the increased levels of safety they offer to the versatility of their applications.

Enhanced Load Stability

An unstable load can be difficult to carry, with stock liable to fall with each movement. This can increase the chances of stock becoming damaged, often resulting in losses for a business, especially if the materials being handled are especially valuable or delicate. Pallet straps secure the load, increase the overall stability of the load and ensure the stock arrives safely.

Increased Safety

Incorrect material handling can often be dangerous, putting employees at risk. Pallet straps can help to improve safety, ensuring the materials will make their way to their final destination without posing a risk to the staff carrying and supporting the supplies.

Cost Efficiency

Many types of pallet straps are designed for multiple uses, making them a cost-effective and environmentally friendly solution for businesses. Unlike single-use plastic wraps or disposable ties, reusable pallet straps, such as Velcro LogiStrap® or heavy-duty polyester straps, can withstand repeated applications without compromising their strength or durability. This makes them a worthwhile investment, particularly for businesses that handle frequent shipments or require continuous load securing in warehouses.

Keeps Information Visible

Wrapping and covering pallets can often obscure the important details listed on stock, preventing them from easily being seen. This means that key safety information can be hidden away, including symbols that convey that a material is hazardous or needs to be kept upright. Thankfully, pallet straps allow all the important information to be seen, while still providing security.

Comparing Pallet Straps with Other Load Securing Methods

Pallet straps are just one of many options when it comes to securing loads to a pallet and preventing them from moving. Below, you can discover how pallet straps can compare to other load-securing methods, from stretch wrap to shrink wrap.

Stretch Wrap

Used to secure stock onto a pallet, stretch wrap is a highly popular product for securing loads effectively. Stretch wrap is typically made from plastic, and is highly flexible which allows it to fit around products loaded on a pallet. This wrap is then typically torn into once the pallet has arrived at its destination, releasing the stock for access.

Shrink Wrap

Another popular packaging technique that can be used to secure pallet loads is shrink wrapping. A special film is wrapped around the pallet load, similar to stretch wrapping. From there, heat will then need to be applied to the film, causing it to shrink and then wrap securely around the stock, creating a secure layer.

Pallet Boxes

Unlike stretch wrap, shrink wrap and pallet straps, pallet boxes are a solid solution that will cover the entire pallet with its load. Pallet boxes can be made of multiple materials, from cardboard to plastic, each with various benefits of their own.

Combing Different Solutions

To properly secure a pallet, many businesses use multiple types of load-securing equipment to prevent stock from moving or falling. This can include wrapping the pallets with shrink wrap and then securing them with pallet straps. With the right supplies, however, it’s often unnecessary to use multiple load-securing methods at once.

About LogiStrap® Pallet Straps

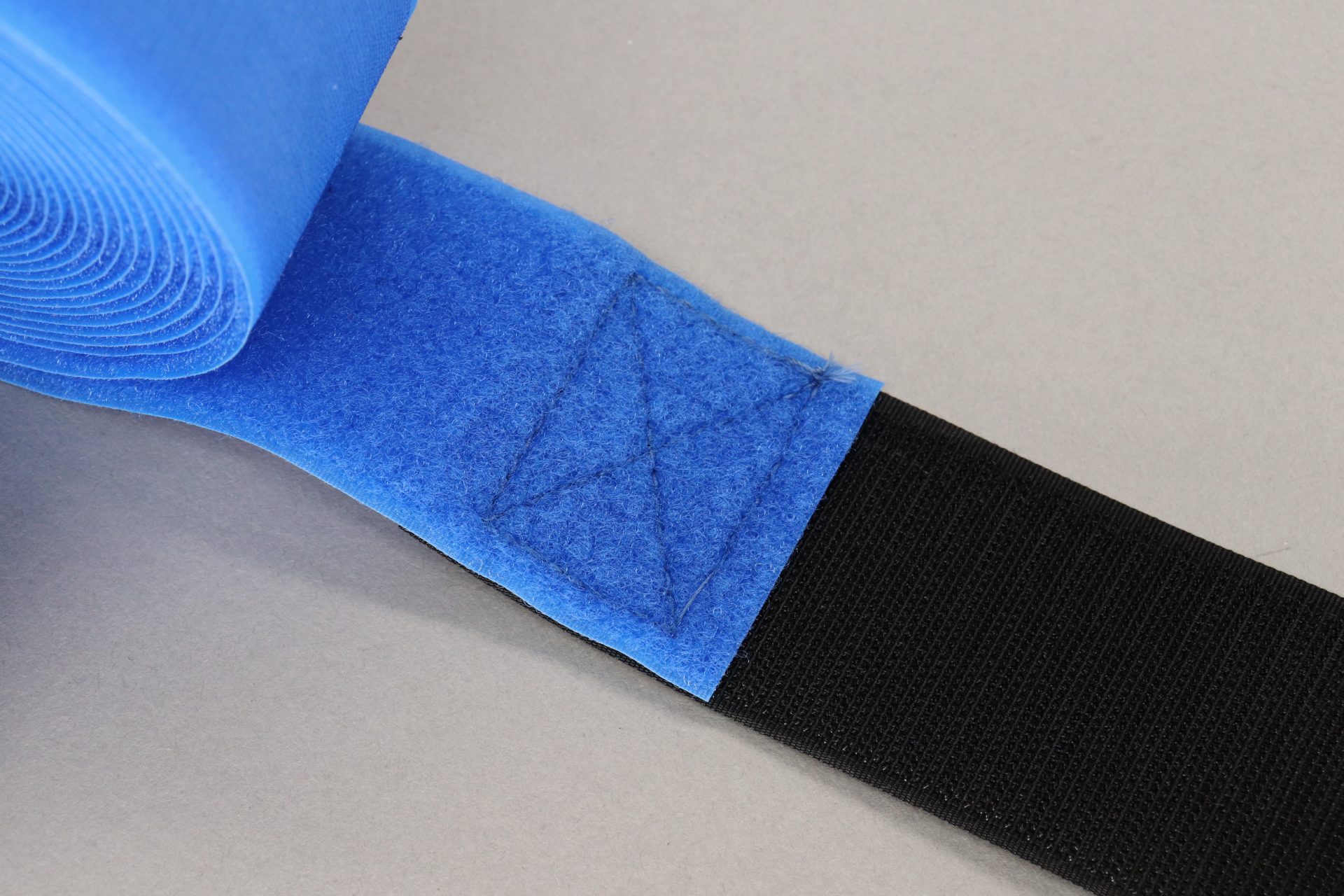

LogiStrap® pallet straps are an innovative, reusable alternative to single-use plastic wrap and traditional strapping methods. Designed for securing palletised goods during storage and transportation, these straps enhance load stability while promoting sustainability and cost efficiency.

Key Benefits

VELCRO® Brand LogiStrap® products are especially beneficial when compared to other material handling products. Unlike shrink wrap, for example, LogiStraps® generate no waste, making them ideal if you’re looking to reduce business waste. They are also reusable, preventing your business from needing to buy multiple single-use products.

Sizes

There is a range of sizes of LogiStrap®, available in various lengths and widths, allowing businesses to easily pick a solution that will work for them. At MPD Hook & Loop, we offer LogiStraps® pallet straps in 4m, 5m, 6m and 7m options.

Colours

The colours of LogiStrap® pallet straps make them easy to identify in the workplace. Each of the different lengths available has its own distinct colour, including blue, green, yellow and orange. These shades are neon and bright, helping them to stand out against a load with ease.

How to Use LogiStrap® Pallet Straps

Ready to get started with LogiStrap® pallet straps? These solutions are incredibly easy to use and require no other equipment to work. Here are some key steps to take if you’re using pallet straps for the very first time.

Choose the Right Size

Pallet straps will be designed for specific capacities, making it important to choose the right one for the load you’re looking to handle. Choosing the correct LogiStrap® pallet straps is essential, as using one that is too weak for the load may result in instability or even damage to goods. If you’re unsure which strap size is appropriate, our team at MPD Hook & Loop would be happy to provide our expert advice.

Position the Strap Around the Load

Once you have chosen the right LogiStrap® pallet strap for your load, unfasten the hook and loop fastening mechanism. You can then position the strap around the load, making sure it will do so securely, and attach the hook and loop fastener to secure the strap in place. For large loads, you may need to use multiple LogiStrap® pallet straps to secure the load properly.

Adjust the Tension

After you have placed the LogiStrap® pallet straps around the load, use the LogiStrap® pallet strap adjustable fastening system and pull the straps tighter to ensure that there is no slack and that the load is firmly held together. You can then verify that the load is truly secure and stable, and will not shift when the pallet is transported. At this point, your pallet is ready for transportation.

VELCRO® Brand Products at MPD Hook & Loop

As a trusted supplier of hook and loop products, at MPD Hook & Loop we offer VELCRO® Brand LogiStraps® that can make handling materials far simpler and safer. We take pride in offering a wide range of high-quality VELCRO® Brand products, allowing our customers to fix and secure materials as they need. You can easily shop our products on our online store at the MPD Hook & Loop website. Please visit our website to learn more about us, or get in touch with us directly for further support.